System

Products

System Field

Woodeumgee E&C system field is essential for securing the optimal cultivation environment within a facility horticulture greenhouse.

The formula for success in facility horticulture depends on a variety of climatic environmental factors and systems, including heating/cooling, air circulation, and CO2. woodeumgee E&C always works with customers to find the best solution and ensure optimal system configuration.

The formula for success in facility horticulture depends on a variety of climatic environmental factors and systems, including heating/cooling, air circulation, and CO2. woodeumgee E&C always works with customers to find the best solution and ensure optimal system configuration.

01

Cooling/heating equipment

Air source heat pump system

Woodeumgee E&C know-how is compiled and utilized as smart farm equipment based on high energy efficiency

This is a system that cools or heats air, supplies it inside, and regulates the temperature to cool and heat the inside of a smart farm. Energy and facility maintenance costs can be economically operated and energy consumption can be minimized.

This is a system that cools or heats air, supplies it inside, and regulates the temperature to cool and heat the inside of a smart farm. Energy and facility maintenance costs can be economically operated and energy consumption can be minimized.

Geothermal heat system

This is a system that regulates the temperature inside a smart farm by utilizing heat energy inside the Earth.

Geothermal heat pumps are used to extract geothermal energy and use it for indoor cooling and heating or hot water supply, providing a sustainable heating and cooling solution due to its high energy efficiency.

Tube rail heating pipe, grow tube heating pipe, top heating heating pipe, snowmelt heating pipe

Geothermal heat pumps are used to extract geothermal energy and use it for indoor cooling and heating or hot water supply, providing a sustainable heating and cooling solution due to its high energy efficiency.

Tube rail heating pipe, grow tube heating pipe, top heating heating pipe, snowmelt heating pipe

Improve production efficiency by utilizing big data from major production facilities based on high energy efficiency

Accumulation, analysis and utilization of cooling and heating big data

Air source cooling and heating system: Air source heat pump

- A system capable of producing hot and cold water, an essential facility for an efficient cultivation environment

- Core equipment that dramatically reduces energy costs and facility maintenance costs

- Production of uniform quality products, control of harvest time, etc.

Cultivation data collection & analysis

- Operate an environmental control system using big data through continuous data collection

- Efficient operation of growth, cultivation, and harvesting through an environmental control system

- Collected data: moisture (humidity), temperature inside the greenhouse, wind direction (speed), amount of carbon dioxide, etc.

02

Semi-enclosed greenhouse

Improve production efficiency by utilizing big data from major production facilities based on high energy efficiency

15-30% increase in profitability compared to regular greenhouses

Optimization of growth environment

Improving the weather environment in the greenhouse

Cost reduction

Optimization of energy and CO2 use

Block harmful factors

Minimize the use of chemical pesticides

Minimize the use of chemical pesticides

Crop growth environment and Improving the quality of agricultural products produced

03

Circulating nutrient solution

cultivation facility

cultivation facility

- Environmental protection by suppressing external discharge of drainage fluid

- Reduce fertilizer costs by recycling drainage

- Save water resources by recycling drainage

- Improving the image of hydroponic crops

- Ultimately, for innovative and sustainable agriculture.

04

Complex environment control and

electricity

electricity

- Presenting a comprehensive control optimal production model in relation to various environments in the above-ground and root zone areas within the facility

- An understanding of each factor that makes up the system is essential for crop growth, environment creation, and integrated management of input resources.

- A system that supplies appropriate nutrients for each crop and controls the temperature and humidity environment so that facility-grown crops can be grown under optimal growth conditions in response to the climatic environment.

Establishment and operation of a big data-based cultivation management system

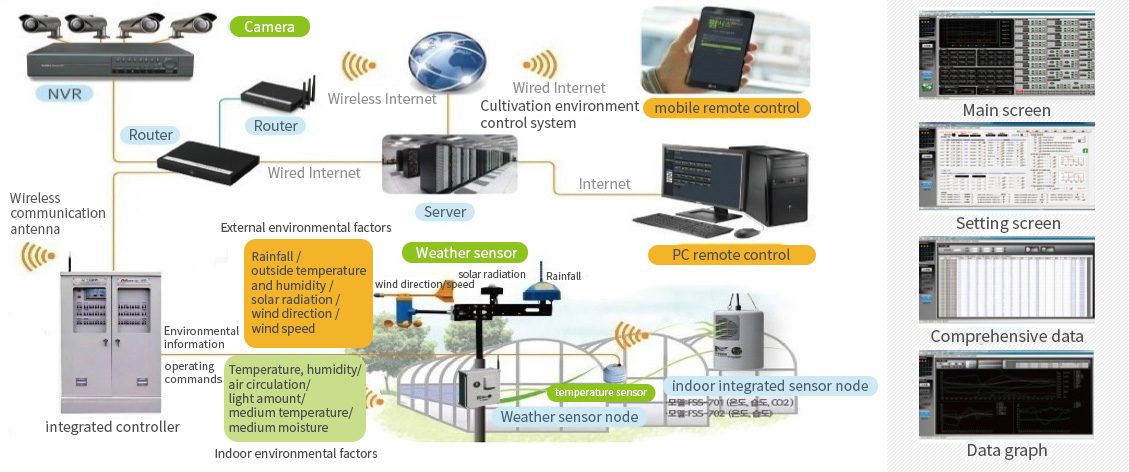

ICT environment management

ICT environment control

- Cooling/heating temperature control system

- Curtain (warmth, shading) / Opening and closing ventilation window

- CO2 / nutrient solution supply

- Flow/exhaust fan (air agitation/exhaust)

Cultivation data collection

- Collection of growth environment data (temperature/humidity, light, irrigation/nutrient solution, etc.)

- Collection of growth information data (length, thickness, number of fruits, etc.)

Big data accumulation, analysis, and utilization

"Improvement of growth algorithm"

Ability to operate a convergence cultivation environment management system using cutting-edge ICT technology

Korea’s only AI DATA smart farm that applies overseas technology to a Korean-style smart farm

Korean-style smart farm through cultivation management experience

Remote control of the cultivation environment using smartphones and PCs, Status inquiry, emergency notification, data inquiry, video confirmation

Cultivation management using big data

Building a system base

Building a system base

Collecting productivity-enhancing cultivation data, Improvement of growth algorithm through utilization

05

Sorting system

Woodeumgee E&C

sorting system

sorting system

- 01

- 02

- 03

- 04

- 05

- 06

01

Agricultural product washing and pre-processing equipment

02

Logistics automation equipment

logistics transport and distribution systems,

Various conveyor automation lines

Various conveyor automation lines

03

Various box making machines, tapping machines,Film sealing machine, banding machine, etc. Packaging equipment

04

Shape and weight (electronic, mechanical) sorter

05

Automatic weighing/ packaging equipment for agricultural products

Computer weighing machine, various packaging machines

06

Agricultural APC automation equipment

State-of-the-art electronic sorting machine, non-destructive sensor, Automatic palletizing, information processing system